SMART SIGNATURES*

A leading Integrated Device Manufacturer ('IDM') and customer met with Yotta for a technology road map session. They had expressed a growing concern of theirs as they continued to press to define the leading edge of semiconductor technology. The clarity of the view they have of the data within their design workflow is becoming less clear. As design feature sizes shrank they were adding more functionality and the functionality more sophisticated. The number of factors that had to be considered were increasing faster than their ability to capture and make intelligible sense of them. Thus, the growing lack of clarity. Yotta had found the same sentiment at the leading edge Foundry, 3rd Party IP and Fabless Companies.

Versions of PDK, cell library, block and chip-level design files within a design workflow are stored, chronologically, on disk. Their use is controlled by the company's Product Lifecycle Management (PLM), configuration and data management systems. Each file, a black box. Its developing meaning not contextual to the rest of the developing dependent data throughout the flow. All of the above companies wanted to have a view of all of the data and have its availability both constant and contextual at the same time. Not only did they want this but some of them had envisioned a higher level view of the data that had been digested so that the detailed meaning of the changes were at their fingertips.

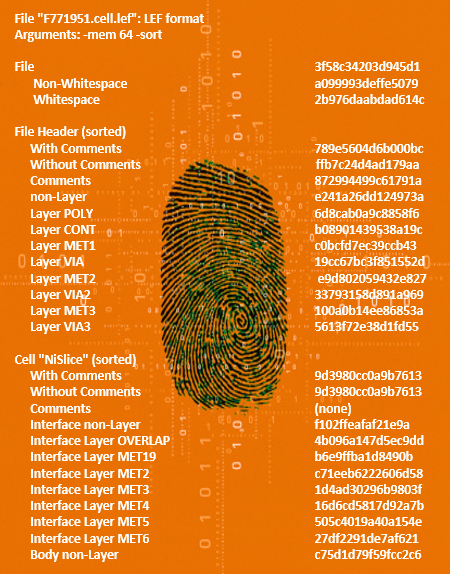

Yotta developed a form of Artificial Intelligence and Intelligent Agent. It can peer into all of the files within this flow. It can comprehend what is there, index it, cross-reference it at the cell leaf level and, in real time, report what has changed and report what within the workflow had led to the changes. Yotta renders the referential and archival index real time by assigning byte sensitive CRC signatures to each of the elements within the indices. The index (above) is a canonical expression of the meaning behind the cell views for SPICE, Liberty, LEF, GDSII, Verilog, VHDL, DEF and OASIS. As the content of a cell view changes, Yotta is able to report what specifically had changed for a cell view and able to report which cell views and modeling/simulation data had been put to use that had caused the change. Anyone who has access to the signature master database has access to this capability. The signatures are smart because they register a change only when something meaningful has changed within the workflow.

With the capability, never again will there be a doubt about what is in use where / never again will there be a doubt about the changes to cell views as the changes will be at their fingertips / never again will there be a bad version of a cell view in use that had been missed. Last, never again will there be a doubt about IP ownership and its use.

Yotta offers both Point Tools that can be manually invoked virtually anywhere with the process development to design to factory workflow. Yotta offers them as a suite of "Design Workflow Auditors". It is developing a SaaS Cloud offering which will be able to report the development of such a globalized workflow in real time across all semiconductor domains and disciplines. You can view more about our Point Tool and Cloud solutions by clicking on their links to the left.

"... The Company's technology plays a substantial role helping us isolate and fix problems before they become silicon issues ..."

Lisa Fisher

Engineering Manager

Texas Instruments

File

Tapeout

In-Place Optimization

Layout Integration

Floor Planning

Logic Design/Synthesis

System Level Design

Library Development/Release

File-level non-layer

File-level layer

File-level non-functional

Cell x

Cell Interface non-layer

Cell Interface layer

Cell non-functional

Cell Body

Cell Body layer

Cell Body layer geometry

Cell Body Layer non-geometry

SS n

SS I

SS II

SS III

.

.

.

.

.

.

.

.

?

?

?

?

Master

Database

PDK

SPICE

Liberty

LEF

GDSII

OASIS

Verilog

VHDL

DEF

Chip

Block

Cell

Fabless/IDM/System OEM

3rd Party IP

Foundry

Indexed File Content by Cell

PLM / Configuration / Data Managment

Smart Signature Generation

API

SS o

SS i

SS ii

SS iii

.

.

.

.

.

.

.

.

New

Release

Smart Signatures

PLM / Configuration / Data Managment

Master Signature Database

OAS = OASIS

GDS = GDSII

Workflow Auditor Point Tools

TM

®

© Getty Images

NEW at Yotta Data Sciences

* US Patents 9,122,825, 8,555,219, 8,266,571 and 7,685,545.

International Patents: China 200980129771.8, Japan 4768896, Korea 10-1580258, Israel 209907, European Patent 2310967.

OASIS® is a Registered Trademark of Thomas Grebinski

© 2008-2024 Yotta Data Sciences, Inc. All rights reserved.

February 16, 2024- Yotta is offering, to qualified partners, a six-month evaluation-period, with support, for its SEMI P39-0416 OASIS Reader/Writer Source Code.

Visit Page: OAS Reader/Writer

Visit Page: OAS Source Code